Tradition meets state-of-the-art logistics | Störtebeker Braumanufaktur relies on VAHLE

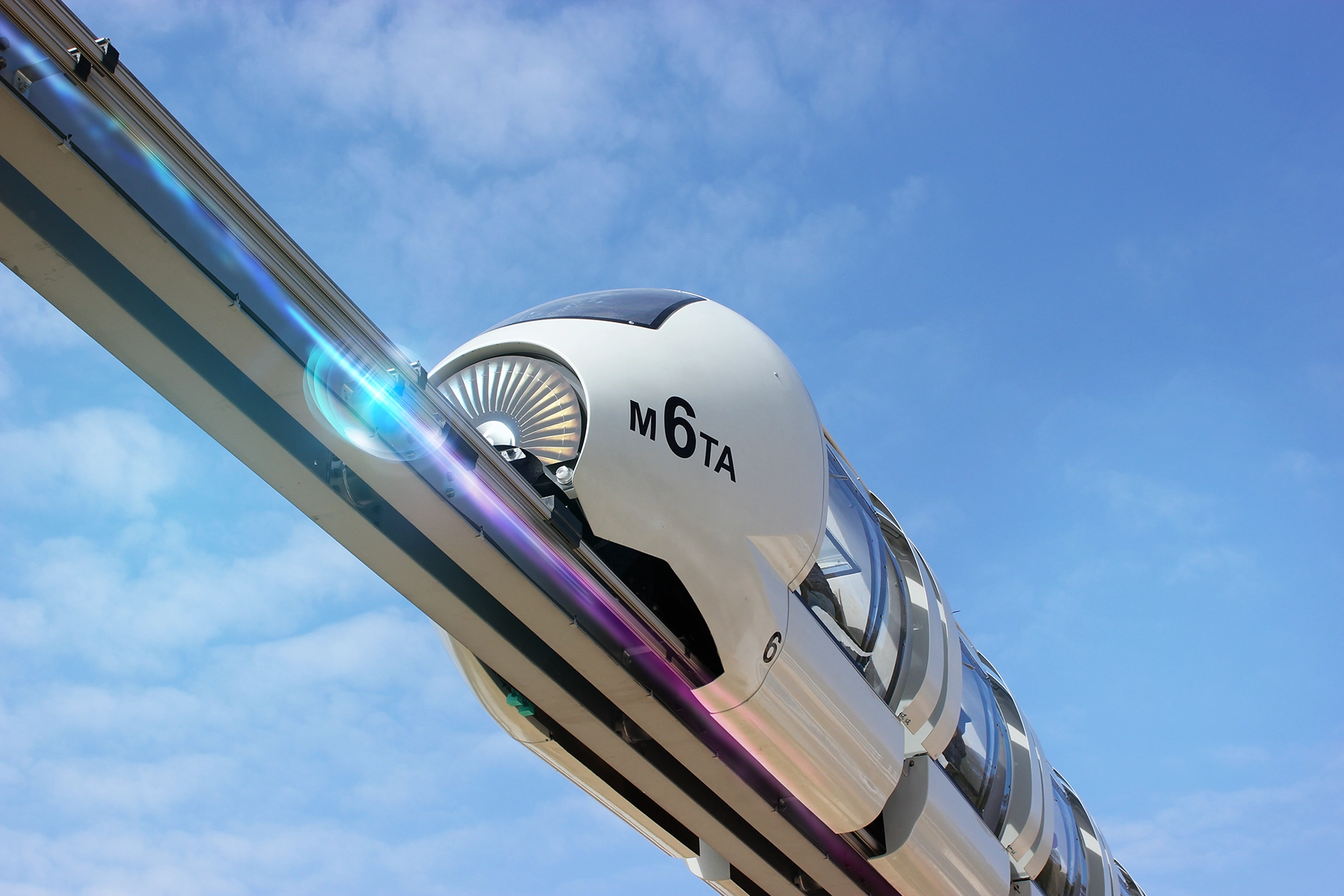

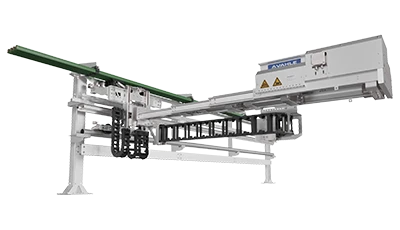

vPOWER U10, VKS10 | vPOS APOS Magnetic | vDRIVE VCSX

The VAHLE fact check

Industry

Intralogistics

Height

30 meters

Length

330 meters

Lanes

6 lanes AKL

VAHLE System

vPower, vPOS, vDrive

Background

Störtebeker Braumanufaktur in Stralsund combines the centuries-old art of brewing with state-of-the-art supply chain technology. As one of the most traditional breweries on the Baltic Sea, known for its brewing specialties, Störtebeker stands for the highest quality and innovative strength in the German beer market. The company maintains an 800-year-old tradition and successfully continues this with over 20 different types of beer.

The challenge

The continuously increasing demand for the popular Störtebeker brewing specialties made an expansion of the production and logistics facilities unavoidable. With the construction of a new bottling plant that fills 40,000 returnable glass bottles per hour and a fully automated high-bay warehouse with a capacity of 30,000 pallet spaces, the challenge was to optimize the material flow and seamlessly integrate the existing systems.

Our solution

VAHLE offered a customized solution to ensure efficiency in logistics and operation of the new filling and storage facility, all in one system. Over 330 meters of our U10 conductor rail systems were used, complemented by the APOS Magnetic Positioning System and the vDRIVE controller VCSX. These were seamlessly integrated with the existing electric floor conveyor (EPB). In the 30-metre-high, fully automated high-bay warehouse, the VKS10 conductor rail ensures reliable power transmission to the storage and retrieval machines in order to guarantee smooth processes in the warehouse's six aisles.

The facts

- End customer: Störtebeker Braumanufaktur

- Customer: GPI GmbH, Germany, System Logistics, Germany

- Year: 2021

- Length: 330 meters

- Solution: VAHLE system, consisting of vPOWER energy transmission via conductor rail (U10, VKS10), vPOS positioning APOS Magnetic, vDRIVE VCSX controller

- Storage capacity: 30,000 pallet spaces

- Future-proof: The flexibility of the VAHLE systems enables future expansions and adjustments to production capacities.