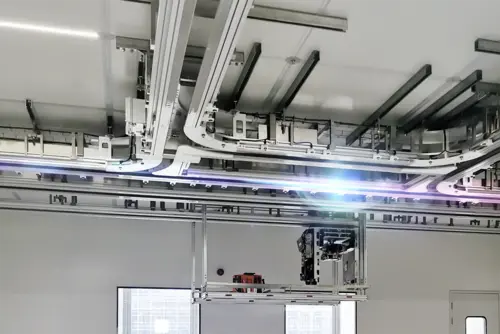

Shuttle warehouse at EDEKA

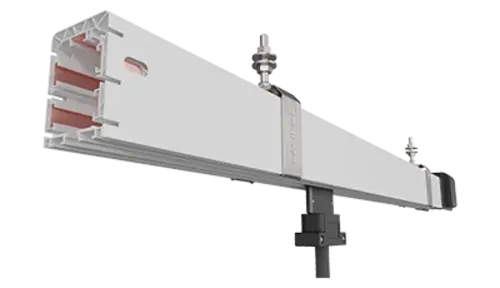

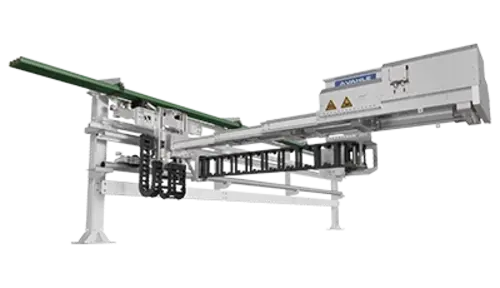

VKS6

The VAHLE fact check

Industry

Length

~8 km (VKS6)

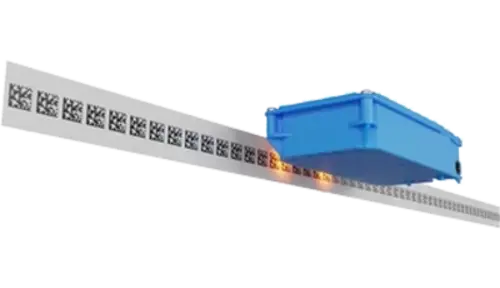

Quantity shuttle

166

Current collector

166 (KEFR double current collector)

Background

VAHLE was already a project partner of VANDERLANDE in 2011 for the then new construction of the logistics center of Edeka-Südwest. Due to the positive cooperation, VAHLE systems were also used for the expansion of the meat logistics center in Rheinstetten. Here, an automatic small parts warehouse with highly dynamic multi-level shuttles was integrated in the fresh meat distribution center of Edeka-Südwest.

Challenge

The expansion had to be carried out during ongoing operation. In addition, a conductor system was required in which the power and emergency stop transmission of the shuttle vehicles ensure trouble-free operation even under extreme external conditions - at temperatures ranging from 0 to -2 degrees Celsius.

Our solution

The robust VKS compact conductor system were used in combination with redundant double current collectors and low-wear graphite current collectors.

Added value for the customer

The customer receives a compact safety conductor system with high operational reserves, which is designed for extreme ambient conditions (temperatures around freezing point). Long maintenance intervals and maximum availability are achieved by using highly wear-resistant graphite current collectors.

Facts

- End customer: EDEKA

- Customer: Vanderlande

- Year: 2020