Reliable energy for storage and retrieval machines in deep-freeze environments

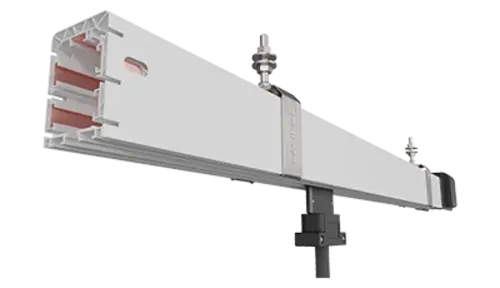

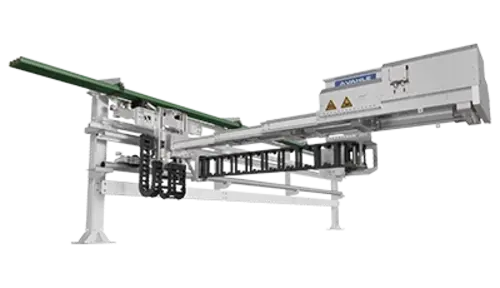

VKS10

The VAHLE fact check

Industry

Intralogistics

Length

~500 m (VKS10)

Extreme conditions

5°C up to -30°C

Background

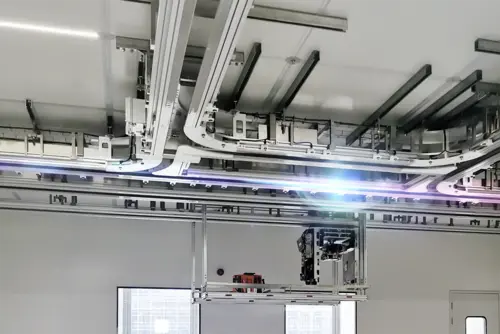

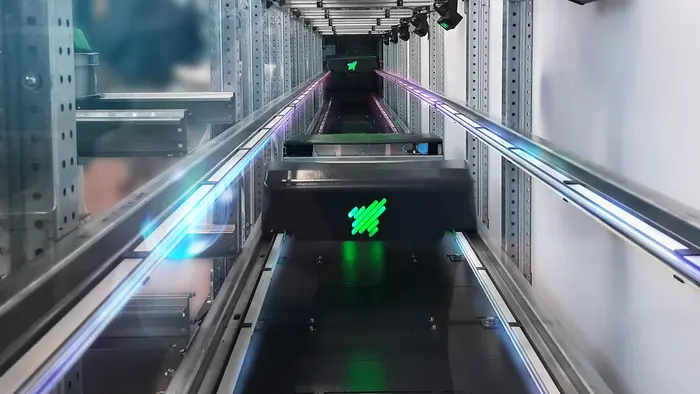

For more than 40 years, Kühlhaus Neuhof AG has been operating a deep-freeze warehouse for the storage of meat and all kinds of food in Gossau, Switzerland. The new building was already completed in 2012. Contrary to expectations, the doubling of capacity realized with the new building at that time was already achieved towards the end of the second year of operation. Subsequently, the realization of the fully automated deep-freeze warehouse was commissioned to Gilgen Logistics AG from Oberwangen, Switzerland. The expansion was officially inaugurated at the end of February 2019. VAHLE is electrifying the fully automated high-bay warehouse here. The capacity of the existing high-bay warehouse was increased from 5,780 to more than 13,700 pallet spaces with two additional fully automated storage aisles. Approx. 500 meters of the 5-pole compact conductor system VKS 10 are used.

Challenge

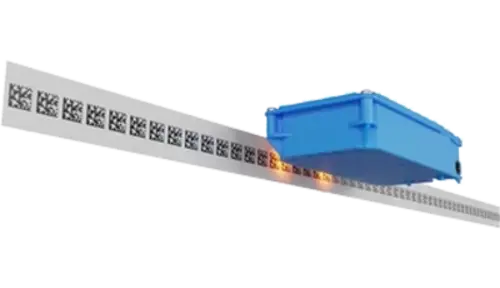

The expansion had to be carried out during ongoing operation. Here, a conductor system was required that would ensure trouble-free operation even under extreme external conditions - at temperatures ranging from 5°C to -30°C degrees Celsius.

Our solution

The robust compact conductor system type VKS 10 is used.

Added value for the customer

The customer receives a compact conductor system with high operational reserves, which is designed for extreme ambient conditions (temperatures far below freezing point).