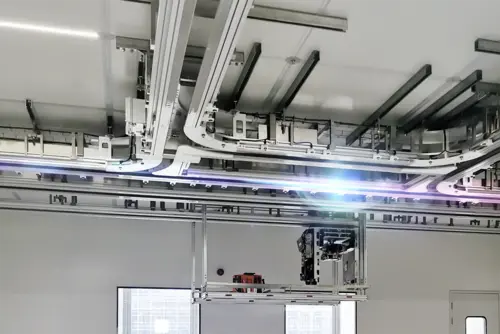

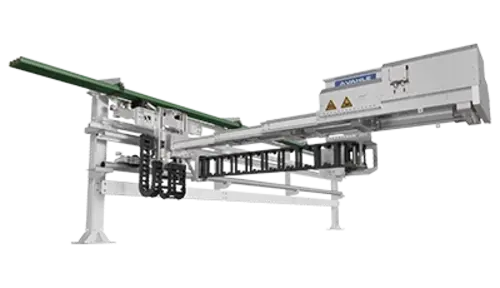

Maintenance-free energy transmission for maximum sorter performance

In action at China Post in Guangzhou

The VAHLE fact check

Industry

System length

2 × 361 m

Performance

1500 W peak per pickup

Maximum driving speed

2.2 m/s

Pickup in use

2 * 18

BACKGROUND

The steady growth in online retail and the associated increase in parcel volumes place high demands on the efficiency of modern sorting systems. In this highly dynamic market environment, maximum system availability and minimum downtimes are crucial for success. These economic factors were clear prerequisites for the planning and implementation of the new sorting system at China Post in Guangzhou.

CHALLENGE

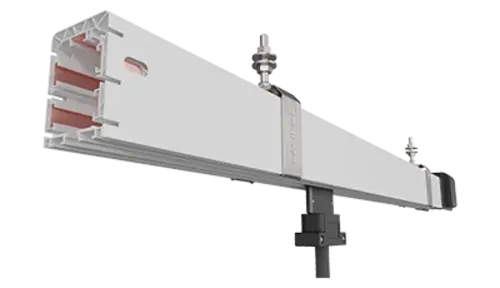

The new, non-contact CPS140 kHz system at China Post represents an innovative step, as the customer and system integrator SPE had previously relied on conventional conductor rail technology. The higher initial investment compared to conventional solutions is a challenge. Nevertheless, the contactless CPS140 system is convincing with its long-term advantages: It is maintenance-free, reduces operating costs and prevents downtime due to the elimination of wearing parts.

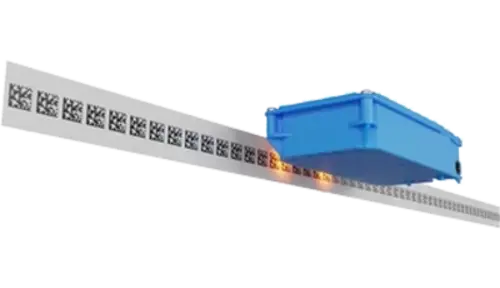

OUR SOLUTION

VAHLE successfully implements the CPS140 system for contactless energy transfer in the sorting plant at China Post. The solution impressed the integrator SPE with its wear-free and stable energy transmission - ideal for applications with the highest demands on availability and production efficiency. The narrow-belt sorters are operated with the CPS140 system and thus receive a consistent and efficient energy supply.

FACTS

- End customer: China Post

- Customer: SPE

- System length: 2 * 361 m

- Pickups: 2 * 18

- Power: 1500 W peak per pickup

- Maximum speed: 2.2 m/s