LogiMAT: VAHLE focuses on predictive maintenance

Visitors to the VAHLE stand C31 in Hall 1 will be able to find out all about the latest products and tools from the energy and data transmission expert.

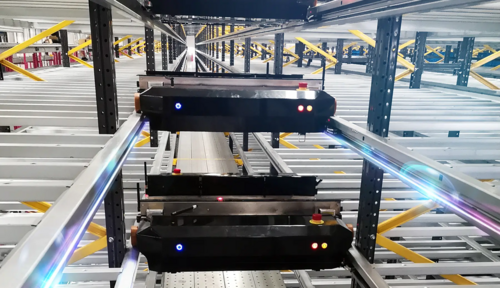

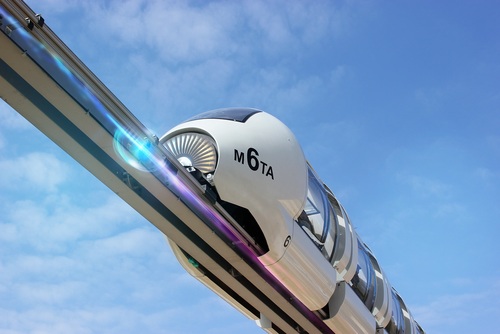

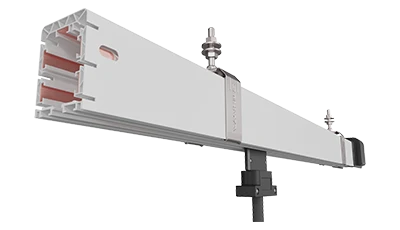

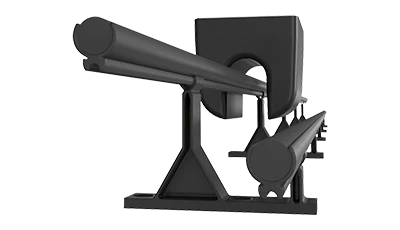

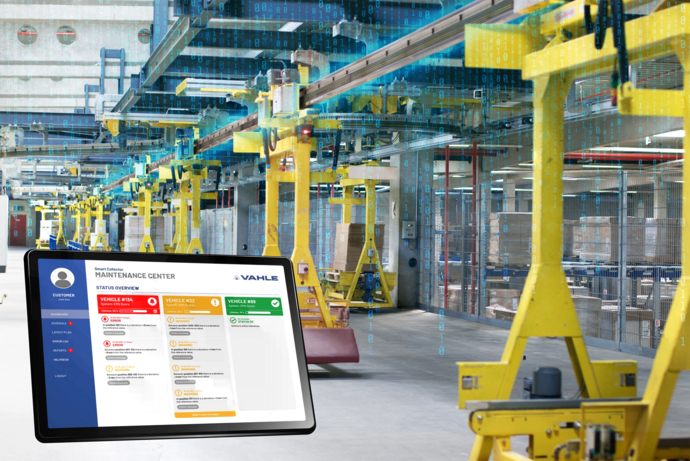

At this year's LogiMAT from March 19 to 21 in Stuttgart, Paul Vahle GmbH & Co. KG will be focusing its trade fair presence on predictive maintenance. The system provider for mobile industrial applications will be demonstrating its globally unique intelligent pantograph system, the Smart Collector, live in action. The predictive maintenance tool detects system anomalies before production downtimes occur. The Kamen-based company will also be presenting its solutions in the field of energy transmission and process automation for mobile applications. VAHLE will also be exhibiting its latest non-contact and conductive energy supply systems specifically for intralogistics applications at stand C31 in hall 1.

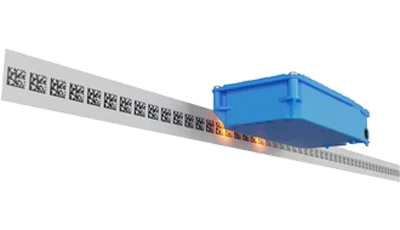

"The highlight at our stand is the Smart Collector, which sets new standards in terms of system availability and productivity and is therefore a pioneering solution for intralogistics. With its ability to detect faults and anomalies at an early stage, it enables a worry-free and more efficient supply chain process," explains Achim Dries, Managing Director of the VAHLE Group. The unique predictive maintenance tool for conductor rail systems is on display as a fully functional exhibit, including the latest developments.

For example, by extending the phase spacing, the Smart Collector can now be used not only in logistics processes with a phase spacing of 14 mm, but also in systems with a spacing of 18 mm or 26 mm. This upgrade opens up a wide range of possible applications in various areas of intralogistics, including skid systems, automated storage systems, pallet floor conveyors, conveyor systems and sorting applications. "The integration of a new thermal sensor also makes a significant contribution to improving process reliability, which in turn leads to increased system availability," emphasizes Dries. This sensor is already being used successfully in several plants and has protected the system there from serious faults. The analysis option is also a useful addition to the existing motion data sensors.

The Smart Collector also plays a decisive role in preventing unplanned system downtimes and makes a significant contribution to making the supply chain process more efficient in the long term. Dries: "Our aim is to increase the efficiency of intralogistics processes and offer our customers innovative solutions for safe and reliable energy and data transmission."

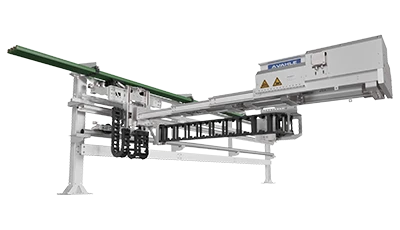

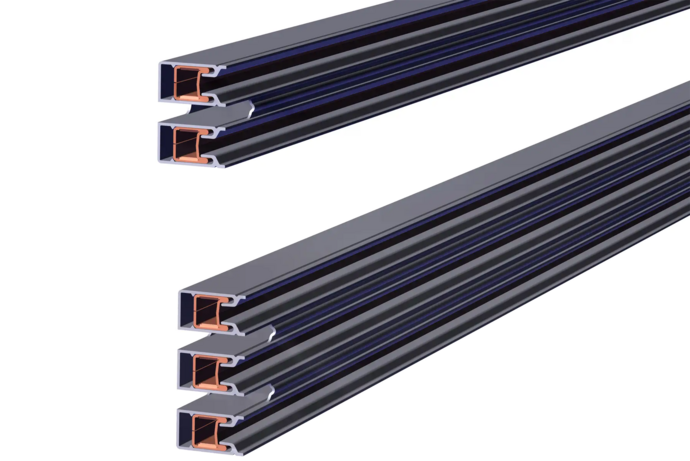

At stand C31 in hall 1, VAHLE will be presenting further tried-and-tested and the latest application solutions for intralogistics systems and specific concepts for intralogistics applications. "We offer the optimum solutions for energy supply and secure data communication for the wide range of applications in intralogistics. We take into account the different needs and requirements of our customers - whether through the use of inductive, wear-free technology or classic conductive VAHLE components, such as our tried-and-tested U20 conductor system," says the Managing Director.

Would you like to learn more about our latest products and solutions? Then simply book a meeting with our experts at LogiMAT 2024 and visit us at our booth C31 in Hall 1.