VAHLE receives electrification order for container blocks at Khalifa Port

VAHLE receives major order for the electrification and automation of container blocks at Khalifa Port, Abu Dhabi. Start of the first phase in summer 2024.

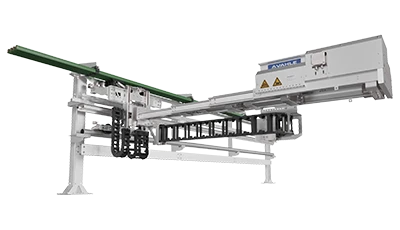

Paul Vahle GmbH & Co. a leading global provider of energy and data transmission solutions for mobile applications and, in particular, an expert in port automation solutions, has secured a significant contract. The CMA CGM Group, a global player of sea, land, air and logistics solutions with headquarters in Marseille, VAHLE was commissioned by the CMA CGM Group, a global player of sea, land, air and logistics solutions, with the electrification and automation of the container blocks in the newly developed port in Abu Dhabi (Khalifa Port).

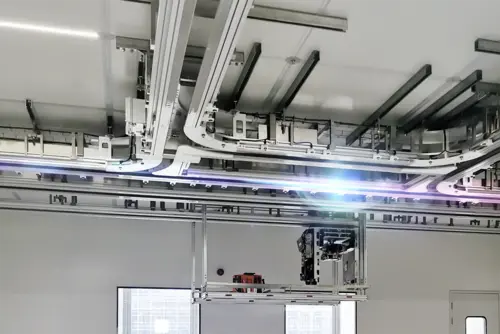

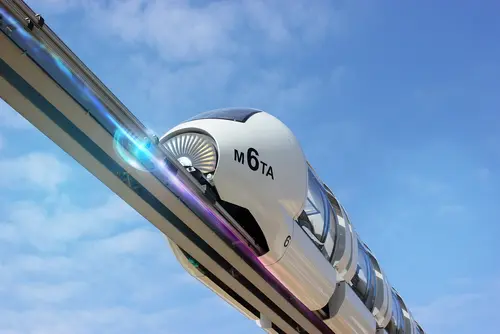

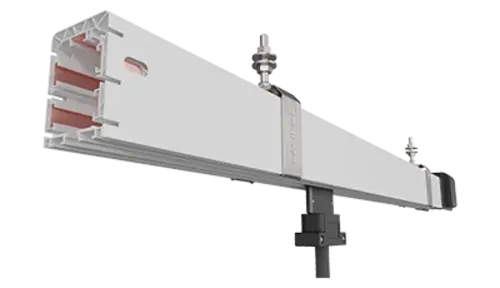

The first phase of the new electrification project, which will start in summer 2024, involves equipping 16 container blocks with VAHLE automation systems. Around 22 kilometers of the U35 conductor system will be installed there. The system will also be equipped with fail-safe SMGX data communication. This will ensure partial automation for the future. The telescopic arms for 20 eRTG cranes will also be supplied by VAHLE, while the cranes themselves will be supplied by a Finnish company.

"After successful projects in the ports of Wilmington and Baltimore in the United States, this is already the third joint project with a Finnish company and, at the same time, the first collaboration with the CMA CGM Group," said Jaroslaw Warzecha, Director Ports at VAHLE. "Due to the tight schedule, the eRTGs will be delivered to Abu Dhabi in individual parts and assembled on site. This will be an enormous challenge given the temperatures in August, as we have already experienced with the AIN Dubai project."

This is another milestone in the history of the VAHLE port division, which was originally founded in 2014. "We are looking forward to launching the project in Khalifa Port on the occasion of our 10th anniversary in 2024," enthuses Warzecha.

The demand for port electrification and terminal automation is enormous worldwide - operators are aiming to reduce their CO2 emissions to zero by 2040. With its innovative and efficient container terminal solutions for zero-emission applications, the Kamen-based company sees itself as an enabler that plays a decisive role in terms of sustainability and CO2 neutrality.

VAHLE will be presenting its innovative developments for a sustainable maritime logistics chain at the TOC Europe trade fair (June 11-13) in Rotterdam.