Robust VAHLE Systems in the Steel Mill: Optimal Performance for thyssenkrupp overhead crane

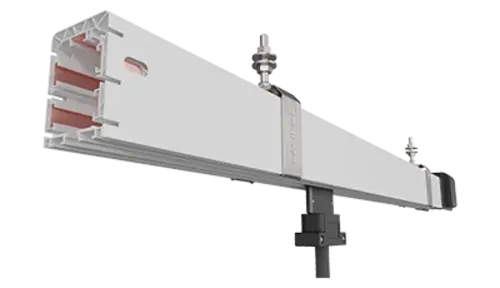

Open conductor system F45/600

The VAHLE fact check

Industry

Crane Technology

Length

300 m (F45)

load capacity

390 Tons

Hoisting speed

10 m/min

Number of poles

7

Background

thyssenkrupp AG is the German heavyweight when it comes to steel production. In order to be able to meet the increasing requirements in the future, the Group decided in 2021 to subject its plant in Duisburg-Beeckerwerth to a retrofit. Part of this was also the installation of a new ladle transport crane weighing almost 900 tons, for which the crane construction expert Köthen and VAHLE were responsible.

Challenge

The ladles, which the twin-girder bridge crane has to lift about 70 times a day, contain 265 tons of liquid steel. The customer had written into the specifications of the contractors that the lifting speed of the existing crane system had to be doubled to approximately 10 meters per minute. In addition, all systems had to be designed for an ambient temperature of 60 degrees Celsius.

Our solution

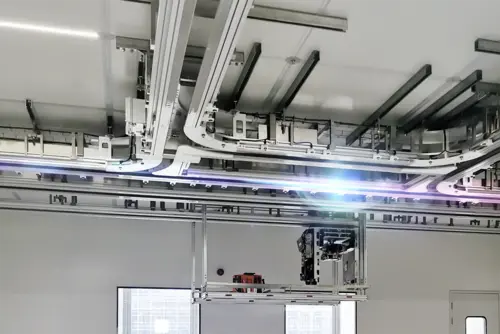

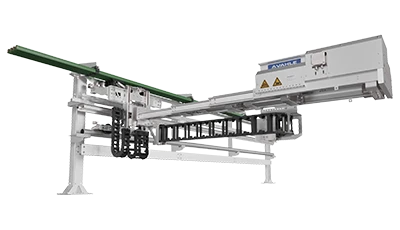

Huge amounts of energy are required for a lifting capacity of about 390 tons. Therefore, Kranbau Köthen relied on a powerful open conductor system from VAHLE. Around 300 meters of the seven-pole F45/600 including two cable carrier ensure trouble-free power transmission. The main hoist is designed with redundancy so that the crane can be moved at least at half speed even if one motor fails.

Facts

- End customer: thyssenkrupp Steel Europe AG

- Customer: Kranbau Köthen

- Year: 2021