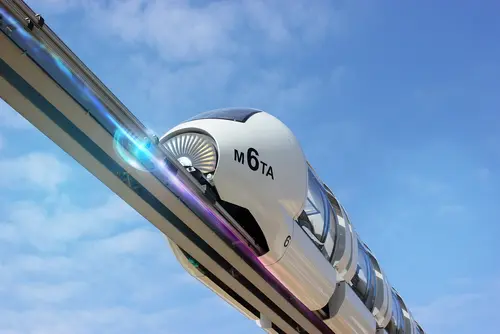

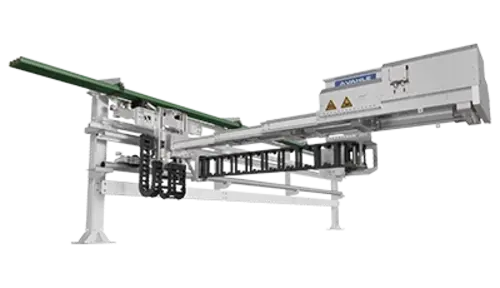

Efficient, automated production requires that all workflows and processes mesh smoothly. This is ensured at VAHLE by production mechanics, who are used wherever components and assemblies are assembled into finished products.

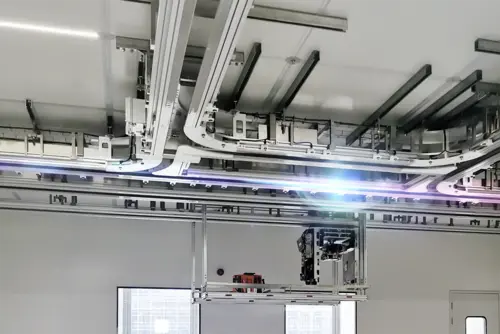

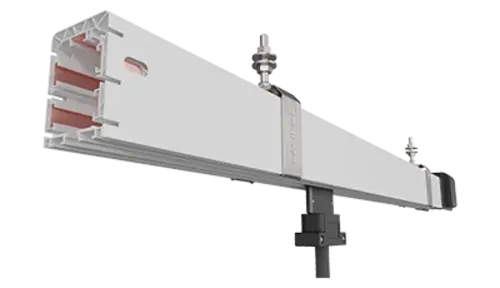

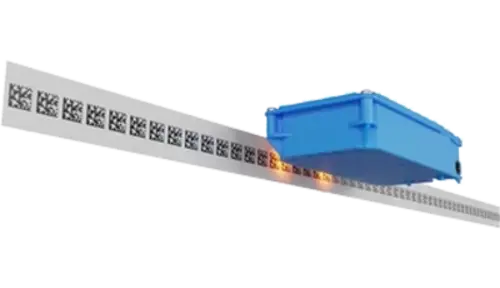

In our in-house training center, you will find the ideal conditions to learn the basics for your profession. Here you will be familiarized with the basics of metalworking by the training team together with other trainees. Machining components by machine or by hand will soon be one of your easiest exercises. You will use the knowledge you have acquired in the various production areas. You will assemble busbars and accessories in production, weld and shape steel in steel construction, turn and mill a wide variety of materials in machining, and assemble and solder electronic components in electrotechnical production. After assembling and processing the components and assemblies, you will check and verify that they have been correctly installed and that your manufactured product functions properly. You will be supported by nice colleagues whom you can always talk to.

If you are interested in this varied profession with us, you should above all have manual skills. A certain basic technical understanding is also helpful.