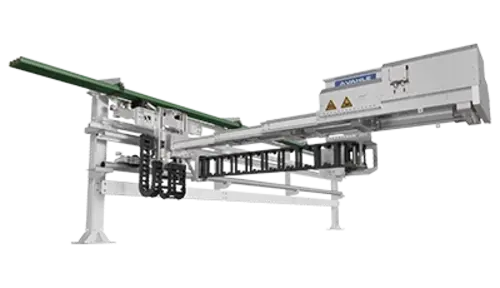

No area of industry can do without the workpieces of cutting machine operators. The cutting machine operator produces the required components on e.g. milling machines or lathes. Do you perhaps already have some experience in working with machines and love to work very precisely and accurately? Are you interested in programming and automation? Then an apprenticeship as a cutting machine operator might be the right thing for you.

In our in-house training center you will find the ideal conditions to learn the basics for your profession. Here, together with other trainees, you will be familiarized with the basics of metalworking by the training team. Manufacturing components on a machine according to technical drawings will be no problem for you. Preparing, assembling and aligning workpiece clamping devices will soon be one of your easiest exercises.

You will use the knowledge you have acquired in the specialist area of machining. There you will deepen your knowledge and skills and prepare for the professional world. You will be supported by nice colleagues whom you can always talk to.

If you are interested in an apprenticeship as a cutting machine operator, you should above all have manual dexterity, diligence and a technical understanding. Planning and organizational skills and a solid basic knowledge of math and physics are also helpful.