Electronics technicians for industrial engineering are true all-rounders when it comes to technical systems. Whether in the home or in industry - nothing works today without electrical installations and systems. Have you ever connected a switch to a lamp or installed a socket? Have you ever wondered how the fuse box in your home works and what an RCD is? Are you handy and have a good understanding of technical processes?

Then an apprenticeship as an electronics technician for industrial engineering might be the right thing for you.

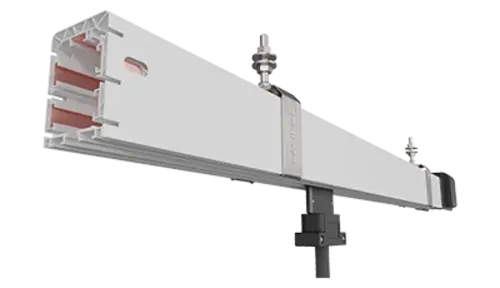

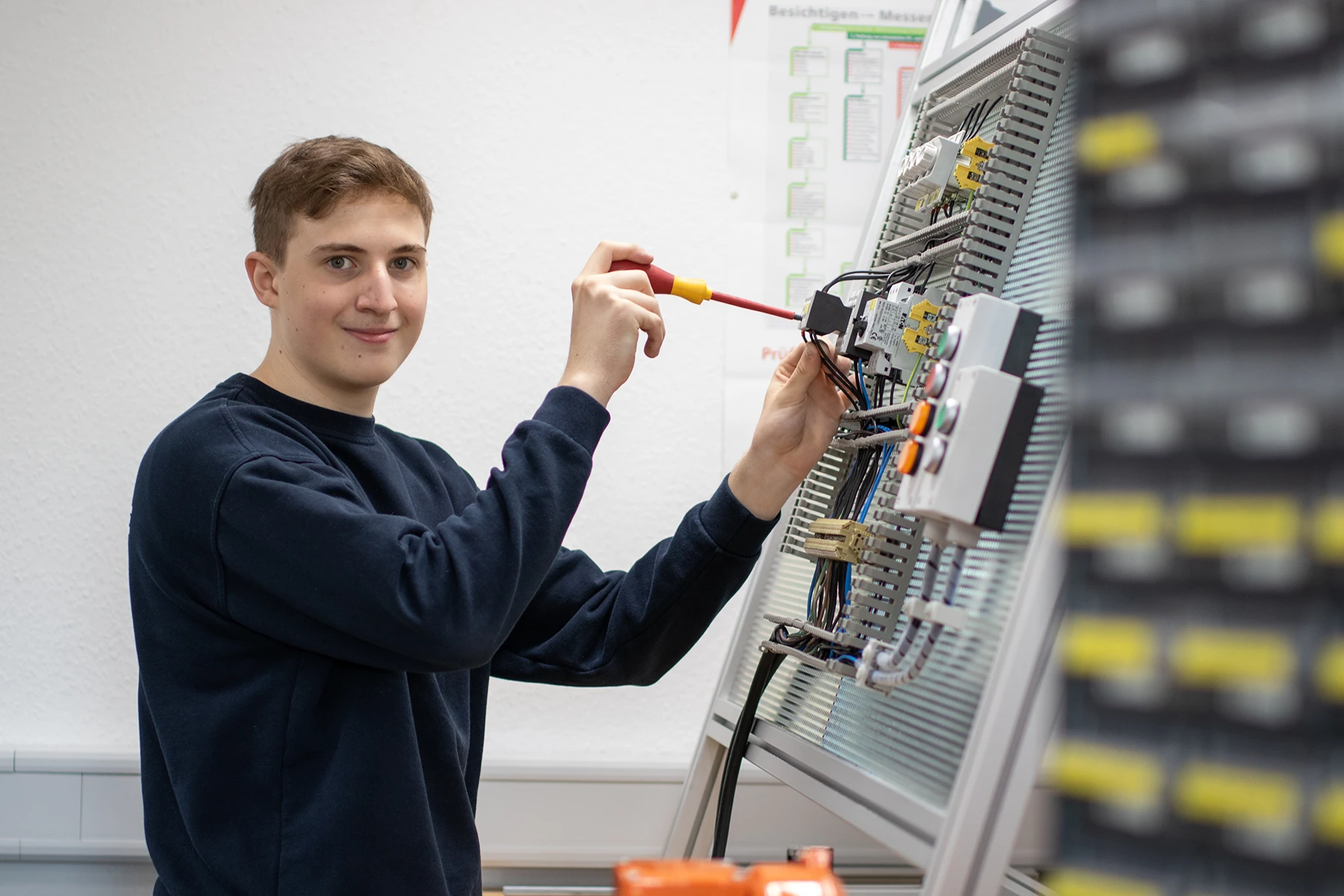

At our in-house training center, you will find the ideal conditions for learning the basics of your profession. The training team will familiarize you with the basics of electrical engineering together with other trainees. Wiring control cabinets or connecting motors is no problem for you. Installing, connecting and maintaining electrical installations and systems will soon be among your easiest exercises.

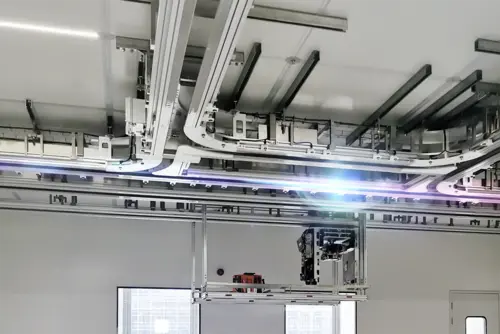

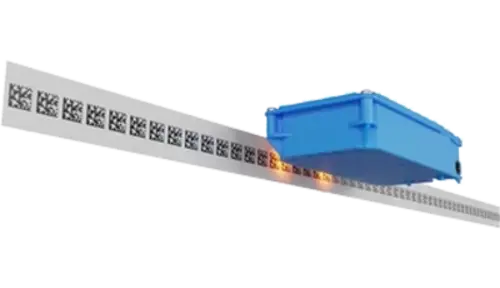

You will use the knowledge you have acquired in the electronics departments. The focus will be on the areas of maintenance, system and control cabinet construction as well as the production of exhibition and sample articles. However, you will also be working on the company's own test site.

You will be supported by friendly colleagues who you are always welcome to talk to. If you are interested in this apprenticeship, you should above all have good dexterity. Communication and organizational skills are also helpful. Technical understanding, manual dexterity, diligence and a solid basic knowledge of math and physics are also an advantage.